Automotive Relays and How They Work

Automotive Relays and How They Work

Relays are an essential component of an automobile's electrical system. They serve as switches that control the flow of electricity to various components, such as the starter, fuel pump, and cooling fan. Understanding how automotive relays work is crucial for troubleshooting and repairing electrical issues in vehicles. In this article, we will delve into the world of automotive relays, discussing their function, types, and operation.

What is an Automotive Relay?

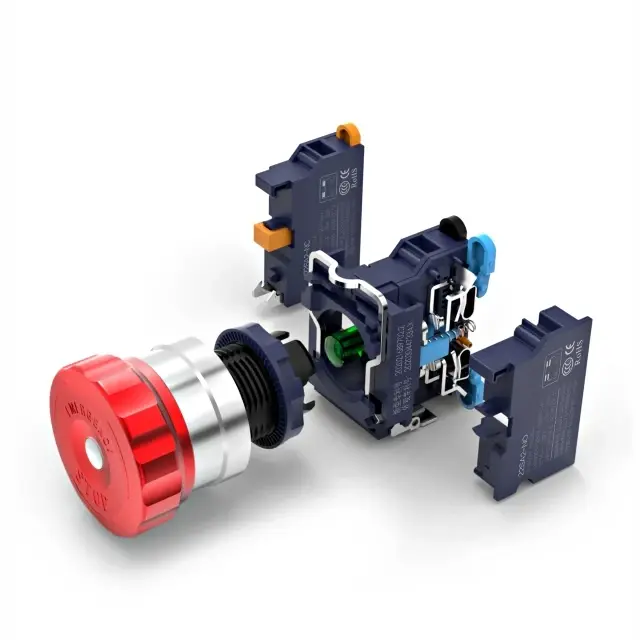

An automotive relay is an electromechanical switch that controls the flow of electricity to various components in a vehicle. It consists of a coil, an armature, and a set of contacts. When current flows through the coil, it generates a magnetic field that attracts the armature, causing the contacts to close and complete the circuit. This allows the relay to control high-current circuits with a low-current signal, making it a crucial component in modern vehicles.

In automotive applications, relays are used to control the operation of components such as the starter, fuel pump, cooling fan, and headlights. They are designed to handle high current loads that would otherwise overwhelm the switches and wiring in the vehicle. By using a relay, the electrical system can be designed to handle heavy loads without compromising the integrity of the wiring or switches.

The use of relays also allows for the centralization of control within the vehicle, with the switches in the dashboard or control module sending low-current signals to the relay, which then controls the high-current circuits. This makes it easier to diagnose and repair electrical issues, as the majority of the heavy-current wiring is concentrated around the relay and its associated components.

Types of Automotive Relays

There are several types of relays used in automotive applications, each designed for specific functions and load requirements. The most common types include:

- Electromagnetic Relays: These relays use an electromagnet to control the position of the armature and the contacts. They are available in both single and double throw configurations, allowing them to control single and dual circuits, respectively.

- Solid State Relays: These relays use semiconductor devices such as transistors to control the flow of current. They have no moving parts, making them more reliable and durable than electromagnetic relays. Solid state relays are often used in applications where high switching speeds and long life are required.

- Time Delay Relays: These relays are designed to control the timing of certain electrical functions, such as turning off the headlights a few seconds after the car is turned off. They are commonly used in automotive lighting and accessory circuits.

- Latching Relays: These relays have two stable states and only require a momentary pulse of current to change states. They are commonly used in battery management systems and other energy-efficient applications.

- High Current Relays: These relays are designed to handle extremely high current loads, such as those found in the starter and fuel pump circuits. They are built with heavy-duty contacts and coils to handle the high power requirements.

Each type of relay is designed to meet specific performance and environmental requirements, ensuring that it can operate reliably in the harsh conditions found in an automotive environment.

How Automotive Relays Work

The operation of an automotive relay is relatively simple, yet crucial for the proper functioning of the vehicle's electrical system. When the relay coil is energized, it creates a magnetic field that attracts the armature, causing the contacts to close. This completes the circuit and allows current to flow to the connected component, such as the starter or fuel pump.

The energization of the relay coil is controlled by a low-current signal from a switch or control module. When the switch or module closes the circuit, current flows through the coil, creating the magnetic field that actuates the relay. This allows the low-current circuit to control the high-current load, enabling the safe and efficient operation of the vehicle's electrical system.

In some applications, the relay may also include additional features, such as diodes for transient suppression, transient voltage protection, or overload protection. These features help to ensure the safe and reliable operation of the relay and the connected components, even in the presence of electrical noise or faults in the vehicle's electrical system.

Testing and Troubleshooting Automotive Relays

When a vehicle experiences electrical issues, such as a non-starting condition or malfunctioning accessories, the electrical relay is often a potential culprit. Testing and troubleshooting automotive relays involves a few simple steps to determine if the relay is functioning properly.

The first step in testing a relay is to visually inspect it for signs of damage, such as burned contacts or melted plastic. If any damage is found, the relay should be replaced with a new unit. If no visible damage is present, the next step is to test the relay using a multimeter or a relay tester.

To test the relay with a multimeter, the resistance of the relay coil and the continuity of the contacts can be measured. If the resistance is significantly higher or lower than the specified value, or if the contacts do not show continuity when the coil is energized, the relay is likely faulty and should be replaced.

If a relay tester is available, it can be used to apply voltage to the relay coil and monitor the state of the contacts. The tester will indicate whether the relay is switching correctly and if the contacts are making good electrical connections. If any issues are found, such as erratic behavior or poor contact, the relay should be replaced.

Troubleshooting relay-related issues in a vehicle requires a systematic approach to identify the root cause of the problem. By following a step-by-step process to test and inspect the relays, it is possible to quickly identify and rectify electrical issues in the vehicle, ensuring its safe and reliable operation.

Common Problems and Solutions with Automotive Relays

Automotive relays are reliable components, but they can experience issues due to wear and tear, environmental factors, or manufacturing defects. Some common problems that can occur with automotive relays include:

- Contacts sticking or arcing: Over time, the contacts inside a relay can become coated with debris or oxidized, leading to poor electrical connections or arcing. This can cause the relay to fail to actuate or create intermittent electrical faults. A common solution to this problem is to replace the affected relay with a new unit.

- Coil failure: The coil inside a relay can fail due to overheating, overvoltage, or mechanical damage. This can cause the relay to fail to actuate or have erratic behavior. If a relay is suspected of having a coil failure, it should be replaced with a new unit to restore proper operation.

- Environmental damage: Relays installed in the engine compartment or other harsh environments can be subject to damage from heat, vibration, and moisture. This can cause the relay to fail prematurely or exhibit unreliable behavior. To address this issue, it is important to use relays that are specifically designed for the environmental conditions present in the vehicle.

- Overloading: Using a relay with a lower current rating than required can cause it to fail due to overheating or damage to the contacts. It is crucial to use relays that are rated for the specific electrical load they will control to prevent this issue.

Proper maintenance and inspection of automotive relays can help mitigate these issues and ensure the reliable operation of the vehicle's electrical system. By using quality relays that are appropriate for the application, and by following recommended inspection and testing procedures, it is possible to minimize the occurrence of relay-related problems in a vehicle.

In summary, automotive relays are essential components of a vehicle's electrical system, allowing for the safe and efficient control of high-current circuits. They come in various types, each designed for specific applications and performance requirements. Understanding how relays work, testing and troubleshooting procedures, and common problems and solutions are crucial for maintaining the reliability of a vehicle's electrical system. By following proper maintenance and inspection practices, it is possible to ensure that the vehicle's relays continue to operate safely and reliably throughout their service life.