The influence of high temperature on the insulation performance of 250VAC magnetic latching relay an

Magnetic latching relays are key components in many electrical systems, providing efficient and reliable switching capabilities. However, when exposed to high temperatures, the insulation performance of these relays can be compromised, leading to potential damage and safety hazards. In this article, we will explore the influence of high temperature on the insulation performance of 250VAC magnetic latching relays and discuss preventive measures to mitigate these effects.

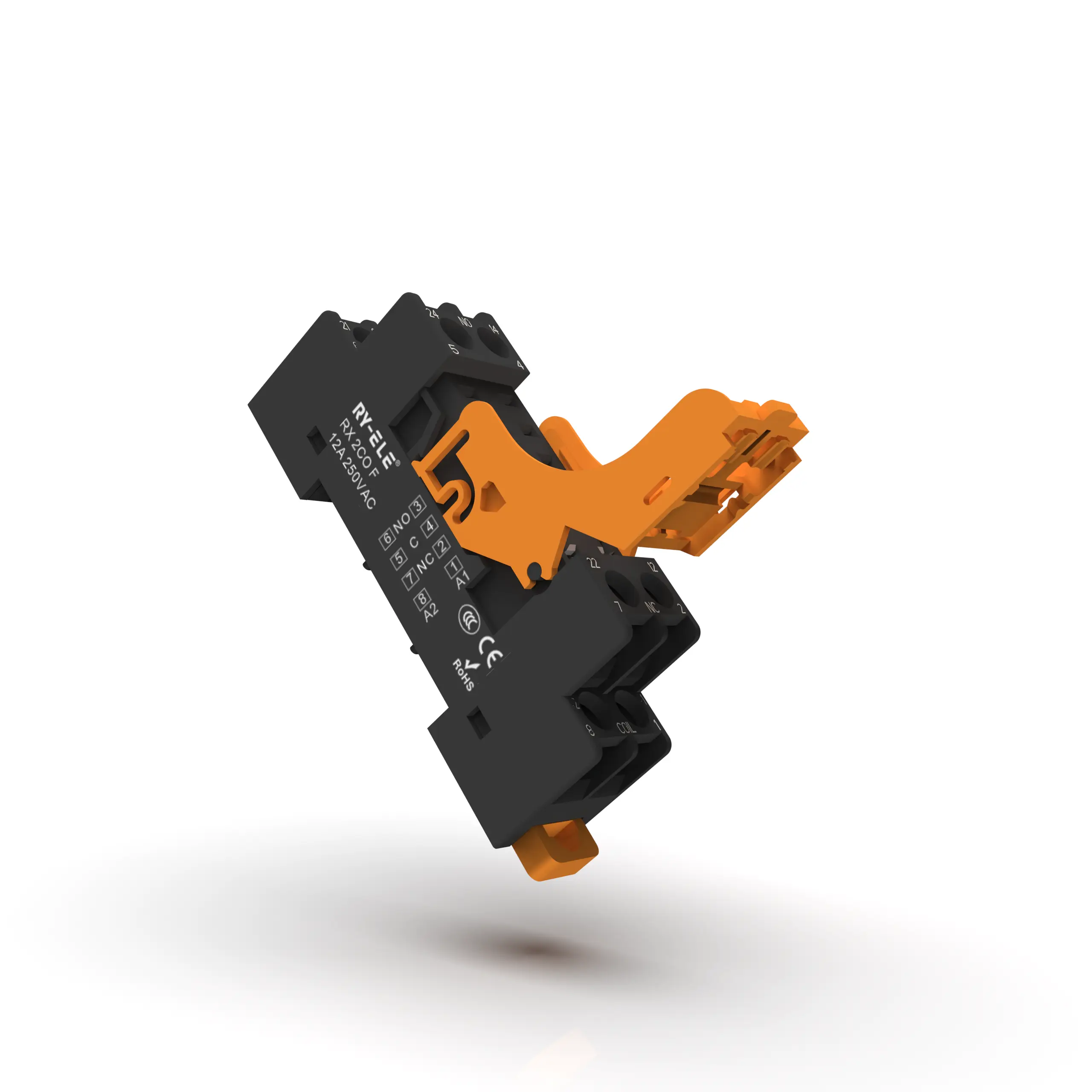

The Basics of 250VAC Magnetic Latching Relays

Magnetic latching relays are electromechanical switches that use a permanent magnet to maintain their state without continuous power. When a brief electrical pulse is applied to the coil, the switch toggles to the opposite state and remains in that position until another pulse is applied. This unique latching feature makes these relays ideal for applications where power consumption is a concern, such as in energy-efficient systems and battery-operated devices.

In the context of 250VAC magnetic latching relays, these relays are specifically designed to handle higher voltage levels, making them suitable for a wide range of industrial and commercial applications. Their robust construction and reliable operation make them essential components in control panels, power distribution systems, and automation equipment. However, the performance of these relays can be significantly affected by high temperatures, which can in turn impact their insulation properties.

The Influence of High Temperature on Insulation Performance

When exposed to elevated temperatures, the insulation materials within a 250VAC magnetic latching relay can deteriorate, leading to a breakdown in insulation resistance and potentially causing short circuits or electrical failures. The primary factors that contribute to this influence include thermal aging, material degradation, and environmental conditions. Thermal aging is the process by which the electrical and mechanical properties of insulation materials change over time when exposed to heat. As temperature increases, the rate of chemical reactions within the materials also increases, resulting in accelerated aging and reduced insulation performance. In addition, material degradation caused by thermal stress and environmental factors such as humidity and contamination can further exacerbate the insulation degradation in magnetic latching relays.

Common Challenges and Failure Modes

One of the common challenges associated with high temperature influences on the insulation performance of 250VAC magnetic latching relays is the occurrence of partial discharge. Partial discharge is a localized breakdown of insulation that can occur within the relay when subjected to high electric fields under thermal stress. This phenomenon can lead to progressive degradation of the insulation and eventual failure of the relay. In addition, thermal aging and material degradation can cause the insulation resistance to decrease, leading to increased leakage current and potential short circuits. Over time, these failure modes can compromise the overall reliability and safety of the electrical system in which the relays are installed.

Preventive Measures for Mitigating High-Temperature Effects

To mitigate the influence of high temperatures on the insulation performance of 250VAC magnetic latching relays, various preventive measures can be implemented. One approach is to utilize insulation materials with high thermal stability and resistance to aging, which can withstand elevated temperatures without significant degradation. Additionally, proper thermal management techniques, such as heat sinking and ventilation, can be employed to minimize the temperature rise within the relay and surrounding components. Ensuring adequate spacing and clearances between conductive elements can also reduce the risk of partial discharge and insulation breakdown. Regular monitoring and maintenance of the relays, including insulation resistance testing and thermal profiling, are essential for early detection of potential issues and timely intervention.

In summary, the insulation performance of 250VAC magnetic latching relays can be significantly influenced by high temperatures, leading to potential failure modes and safety concerns. Understanding the underlying mechanisms of this influence and implementing effective preventive measures are crucial for ensuring the reliability and longevity of these relays in electrical systems. By addressing the challenges associated with high temperature effects and adopting proactive strategies, engineers and designers can enhance the performance and safety of 250VAC magnetic latching relays in various applications.