The key role of electrical relays in power electronic equipment

The Key Role of Electrical Relays in Power Electronic Equipment

Electrical relays are crucial components in power electronic equipment, serving as essential devices for controlling and protecting circuits. They play a key role in ensuring the safe and efficient operation of various electrical systems, from industrial machinery to consumer electronics. This article will delve into the importance of electrical relays in power electronic equipment, exploring their functions, types, and applications.

Understanding Electrical Relays

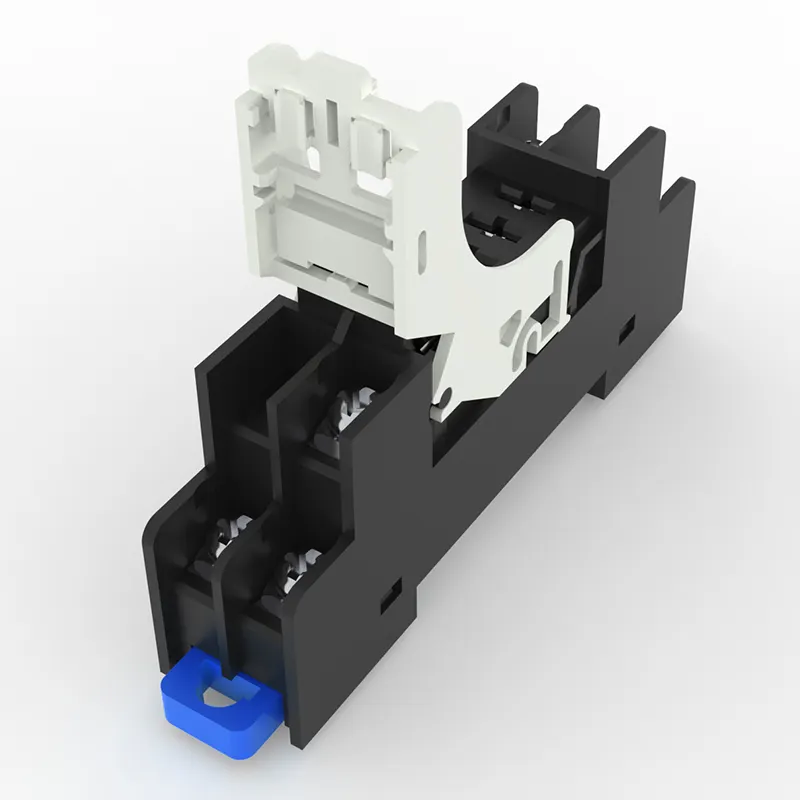

Electrical relays are electromechanical switches that are used to control the flow of electricity in a circuit. They work by opening or closing the contacts in response to a signal from a control system. This enables them to effectively manage the flow of power and provide protection against overcurrent, overvoltage, and other electrical faults. The key components of an electrical relay include a coil, an armature, contacts, and a spring. When a current is passed through the coil, it creates a magnetic field that attracts the armature, causing the contacts to either open or close, depending on the relay type.

Electrical relays come in various forms, such as electromechanical relays, solid-state relays, and reed relays. Each type has its unique characteristics and is suitable for specific applications. Electromechanical relays use an electromagnetic coil to mechanically operate the contacts. Solid-state relays, on the other hand, use semiconductors to switch the current without any moving parts, resulting in faster response times and longer lifespans. Reed relays utilize magnetic fields to control reed switch contacts, offering high isolation and low contact resistance.

The versatility of electrical relays makes them indispensable in power electronic equipment, where they are used for various functions, including switching, protection, and signal isolation. They are commonly employed in electric motors, heating systems, lighting controls, and automotive applications. Additionally, relays play a crucial role in safety-critical systems, such as in industrial machinery, where they provide emergency shutdown and fault protection.

Role of Electrical Relays in Power Electronic Equipment

In power electronic equipment, electrical relays serve as essential components for controlling the flow of electricity and protecting the system from potential hazards. One of the primary functions of relays is to act as switches, allowing them to control the operation of various electrical loads. For instance, relays can control the starting and stopping of motors, the switching of lighting circuits, and the operation of heating elements in industrial processes. By providing a means for remote and automated control, relays enhance the efficiency and flexibility of power electronic systems.

Another critical role of electrical relays in power electronic equipment is to provide protection against electrical faults. Relays are designed to quickly detect abnormal operating conditions, such as overcurrent or overvoltage, and take appropriate actions to mitigate the risk of damage to the equipment and personnel. For example, in an electrical distribution system, relays can be used to trip circuit breakers in response to a fault, isolating the affected area and preventing further damage. This protective function is vital for ensuring the safety and reliability of power electronic equipment in various applications.

Furthermore, electrical relays play a key role in signal isolation, where they are used to electrically separate different parts of a circuit. This is particularly important in applications where the control signals and power circuits need to be isolated to prevent interference and ensure accurate signal transmission. By providing a means for galvanic isolation, relays help to enhance the stability and performance of power electronic systems, especially in high-voltage and high-power applications.

In summary, the role of electrical relays in power electronic equipment is multifaceted, encompassing functions such as switching, protection, and signal isolation. Their ability to control the flow of electricity, provide protective measures, and ensure signal integrity makes them indispensable components in a wide range of applications, from industrial automation to consumer electronics.

Types of Electrical Relays

There are several types of electrical relays, each designed to suit specific applications and performance requirements. Understanding the different relay types is crucial for selecting the most suitable device for a particular power electronic system.

Electromechanical relays, also known as mechanical relays, are the traditional type of relays that use an electromagnetic coil to operate the contacts. When a current is passed through the coil, it generates a magnetic field that attracts the armature, causing the contacts to either open or close. Electromechanical relays are known for their durability and ability to handle high currents and voltages, making them suitable for a wide range of applications, including industrial control, automotive, and power distribution systems.

Solid-state relays (SSRs) are a newer type of relay that use semiconductor switching elements, such as thyristors or transistors, to control the flow of current. SSRs do not have any moving parts, which results in faster switching times, higher reliability, and longer lifespans compared to electromechanical relays. They are widely used in applications where silent operation, low power consumption, and high-speed switching are essential, such as in HVAC systems, medical equipment, and digital control systems.

Reed relays are a special type of relay that utilize reed switches, which are comprised of two flexible metal reeds enclosed in a glass tube filled with inert gas. When a magnetic field is applied, the reeds attract, causing the contacts to close. Reed relays offer high isolation, low contact resistance, and excellent hermetic sealing, making them suitable for applications where small size, low power consumption, and reliable performance are required, such as in telecommunications, test and measurement equipment, and instrumentation.

Another type of relay is the latching relay, which is designed to maintain its contact state without continuous coil power. Once energized, latching relays retain their position until an opposite polarity pulse is applied to the coil, causing the contacts to switch. Latching relays are commonly used in power-off applications, such as in battery-operated devices, where energy efficiency and long-term operation are critical.

Finally, there are protective relays, which are specifically designed to monitor the electrical parameters in a power system and initiate appropriate actions in the event of a fault or abnormal condition. Protective relays can provide functions such as overcurrent protection, overvoltage protection, thermal overload protection, and earth fault protection, helping to safeguard the power system from damage and ensure the safety of equipment and personnel.

It is essential to consider the specific requirements and performance characteristics of a power electronic system when selecting the appropriate type of electrical relay. Factors such as switching speed, contact ratings, operating environment, and reliability should be carefully evaluated to ensure the optimal performance and longevity of the equipment.

Applications of Electrical Relays

Electrical relays find extensive usage in various applications across different industries, where they play a critical role in controlling, protecting, and isolating electrical circuits. Some of the key applications of electrical relays include:

Industrial Automation: In industrial automation and control systems, relays are used to control the operation of motors, solenoids, and other electromagnetic devices. They provide a reliable and flexible means for implementing complex control strategies, such as sequential logic, time delay, and interlocking functions. Relays are also employed in safety-critical applications, where they provide emergency stop, fault detection, and machinery protection.

Power Distribution: Electrical relays are integral to power distribution systems, where they protect equipment and personnel from electrical faults and overloads. They are used in circuit breakers, reclosers, and protective relays to monitor the electrical parameters and initiate corrective actions in the event of a fault. Relays also play a key role in load shedding and system reconfiguration to maintain the stability and reliability of the power grid.

Consumer Electronics: In consumer electronics devices, relays are utilized for various switching and control functions, such as in audio amplifiers, telecommunication equipment, and home appliances. They enable efficient power management, signal routing, and user interface control, enhancing the performance and usability of electronic products.

Automotive Systems: Relays are widely used in automotive applications to control the operation of lighting systems, motors, and other electrical components. They provide reliable switching for power distribution, actuation of vehicle functions, and protection against short circuits and overcurrent conditions. Relays are also employed in automotive safety systems, such as airbag deployment and antilock braking, where they ensure rapid and precise response to critical events.

Telecommunications: The telecommunications industry relies on relays for signal routing, line switching, and signal conditioning in network equipment, such as telephone exchanges, cellular base stations, and data communication systems. Relays offer high isolation, low insertion loss, and superior reliability, making them suitable for demanding telecommunications applications.

In summary, the applications of electrical relays are diverse and encompass a wide range of industries, from industrial automation to consumer electronics and telecommunications. Their ability to provide reliable switching, protection, and signal isolation makes them essential components for ensuring the efficient and safe operation of electrical systems in numerous applications.

Advancements in Electrical Relays

The field of electrical relays has witnessed significant advancements in recent years, driven by technological innovations and evolving performance requirements. These advancements have led to the development of new relay designs, improved functionality, and enhanced performance characteristics, addressing the demands of modern power electronic systems.

One of the notable advancements in electrical relays is the integration of advanced control and communication features. Modern relays are equipped with microprocessor-based control units, enabling them to implement complex protection and control algorithms, as well as to communicate with external devices through standard communication protocols. This provides greater flexibility for implementing advanced protection schemes, such as differential protection, adaptive relaying, and intelligent load shedding, as well as for integrating relays into supervisory control and data acquisition (SCADA) systems.

Another significant advancement is the incorporation of solid-state technology in relay designs. Solid-state relays (SSRs) have gained popularity due to their fast switching speeds, high reliability, and silent operation, making them suitable for applications where electromechanical relays may be limited. The use of advanced semiconductors, such as insulated gate bipolar transistors (IGBTs) and silicon carbide (SiC) devices, has enabled the development of SSRs with higher power handling capabilities and improved thermal performance, extending their applicability to high-power and high-temperature environments.

In response to the growing demand for energy-efficient and environmentally friendly solutions, there has been a focus on developing relays with lower power consumption and improved energy efficiency. Efforts have been made to optimize the design of relay coils, reduce power losses during switching operations, and enhance the overall efficiency of relay components. This has led to the emergence of energy-efficient relays that help minimize power consumption and contribute to sustainable energy management.

Advancements in materials science and manufacturing processes have also contributed to the development of miniature and high-performance relays. New materials with improved electrical and mechanical properties, such as nanomaterials and advanced polymers, have enabled the miniaturization of relay components while maintaining high reliability and long-term performance. Additionally, advanced manufacturing techniques, such as 3D printing and microfabrication, have facilitated the production of complex relay structures with precise control over dimensions and tolerances.

The integration of smart features and diagnostics capabilities is another area of advancement in electrical relays. Smart relays are equipped with built-in sensors, monitoring functions, and self-diagnostic capabilities, enabling them to continuously assess their operating conditions, detect potential faults, and provide early warnings of impending issues. This proactive approach to maintenance and fault detection helps enhance the reliability and availability of power electronic systems, reducing the risk of unexpected downtime and equipment failures.

Overall, the advancements in electrical relays have paved the way for enhanced performance, increased functionality, and expanded applicability in modern power electronic equipment. The integration of advanced control and communication features, the adoption of solid-state technology, the focus on energy efficiency, the development of miniature and high-performance relays, and the integration of smart features and diagnostics capabilities have collectively contributed to the evolution of electrical relays into sophisticated and reliable components for diverse applications.

Conclusion

Electrical relays play a key role in power electronic equipment, providing essential functions for controlling and protecting electrical circuits. Their ability to switch, protect, and isolate signals makes them indispensable components in a wide range of applications, spanning from industrial automation to consumer electronics. The various types of relays, such as electromechanical relays, solid-state relays, reed relays, and latching relays, offer diverse performance characteristics to address specific application requirements. Furthermore, the advancements in relay technology have led to the development of more advanced, reliable, and efficient relay designs, incorporating features such as advanced control and communication, solid-state technology, energy efficiency, miniature size, and smart diagnostics capabilities.

As power electronic systems continue to advance and evolve, electrical relays are expected to play an increasingly significant role in ensuring the safe, efficient, and reliable operation of electrical equipment. Their ability to adapt to changing performance requirements and technological developments makes them essential components for meeting the demands of modern power systems. With ongoing innovation and research in relay technology, the future holds promising opportunities for further enhancements in performance, functionality, and applicability of electrical relays in power electronic equipment.