What Is A Terminal Block?

Terminal blocks are a crucial component in electrical engineering and are widely used in various industrial and commercial applications. Despite their small size, terminal blocks play a significant role in connecting and securing electrical wires and components, making them an essential part of any electrical system.

Understanding Terminal Blocks

A terminal block, also known as a connection terminal, is a modular block with an insulated frame that secures two or more wires together. Terminal blocks typically consist of a metal strip or plate with clamps or screws to secure and connect wires. They are designed to provide a safe and efficient way to connect multiple electrical wires or components. Terminal blocks are used to connect and distribute power, as well as to enable troubleshooting and maintenance of electrical systems.

Terminal blocks come in various types, including modular terminal blocks, barrier terminal blocks, DIN rail terminal blocks, and PCB terminal blocks. Each type is designed for specific applications and environments, with unique features and characteristics that make them suitable for different electrical setups.

Types of Terminal Blocks

1. Modular Terminal Blocks

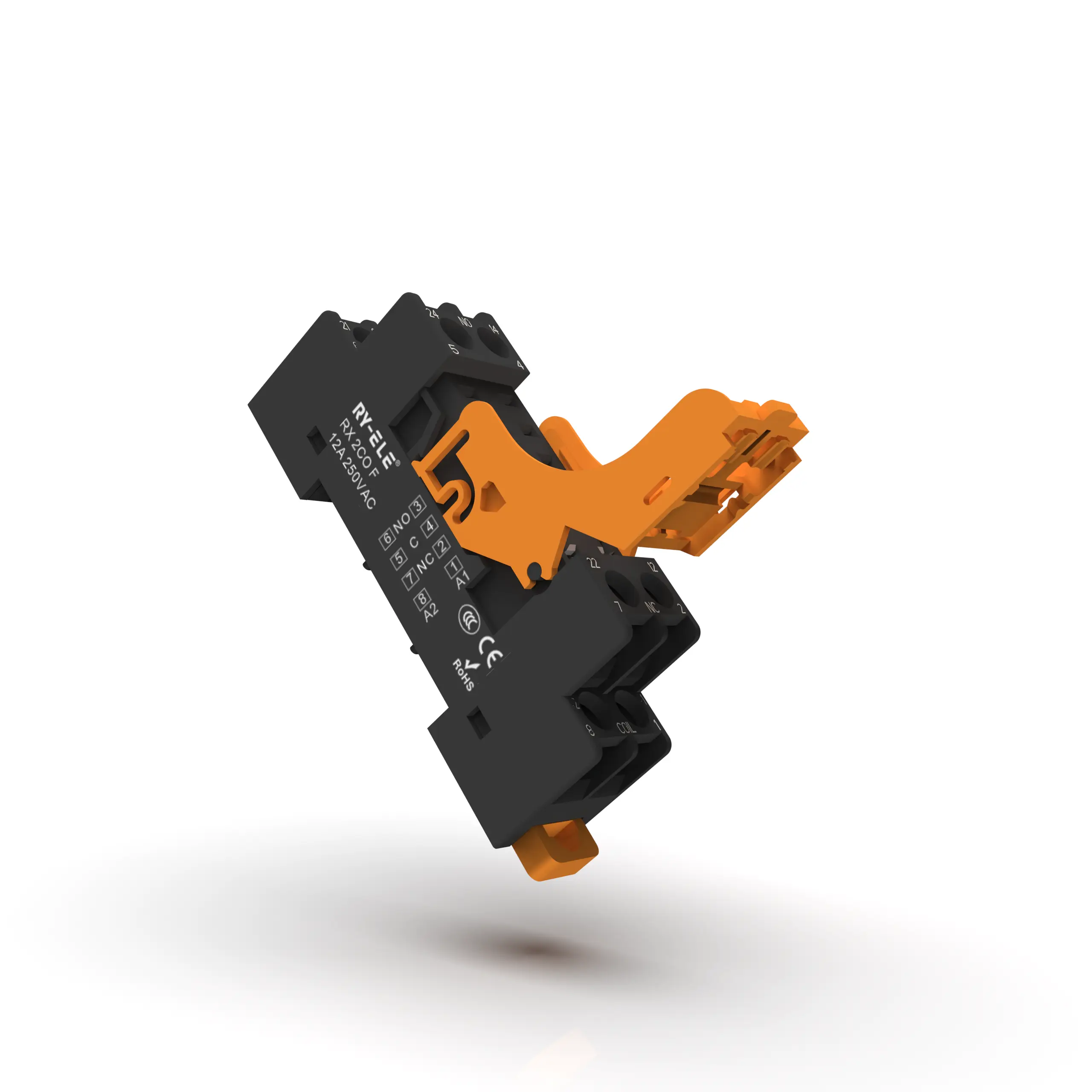

Modular terminal blocks are one of the most common types of terminal blocks used in electrical installations. They are designed to provide a flexible and modular way to connect wires and components. Modular terminal blocks consist of individual blocks that can be mounted on a DIN rail or a mounting panel, allowing for easy installation and reconfiguration of wiring.

These terminal blocks are available in various configurations, including feed-through, ground, disconnect, fuse, and sensor terminal blocks, making them suitable for a wide range of applications. They are often used in control cabinets, power distribution panels, and industrial automation systems.

2. Barrier Terminal Blocks

Barrier terminal blocks are designed to provide a high level of safety and protection for electrical connections. They consist of insulated barriers that separate the connection points, preventing accidental contact and short-circuiting. Barrier terminal blocks are commonly used in high-voltage and high-current applications where safety is a top priority.

These terminal blocks are available in single, double, or triple-level configurations, allowing for multiple wire connections in a compact space. They are often used in power distribution systems, motor control centers, and heavy machinery.

3. DIN Rail Terminal Blocks

DIN rail terminal blocks are designed to be mounted on standard DIN rails, providing a secure and space-efficient way to connect and distribute power. These terminal blocks are widely used in industrial and commercial applications, where they can be easily installed and repositioned as needed.

DIN rail terminal blocks come in various styles, including screw-type, spring-cage, and push-in terminal blocks, offering flexibility and ease of use for different wiring requirements. They are often used in control panels, switchgear, and equipment racks.

4. PCB Terminal Blocks

PCB terminal blocks are designed to be mounted directly onto printed circuit boards (PCBs), providing a convenient way to connect wires and components in electronic devices and equipment. These terminal blocks are compact and lightweight, making them suitable for space-constrained applications.

PCB terminal blocks come in various configurations, including wire-to-board, wire-to-wire, and wire-to-device terminal blocks, offering flexibility and versatility for different PCB designs. They are often used in consumer electronics, automotive systems, and industrial control devices.

Benefits of Using Terminal Blocks

Terminal blocks offer numerous benefits for electrical installations, making them an ideal choice for connecting wires and components in various applications. Some of the key benefits of terminal blocks include:

1. Simplified Wiring: Terminal blocks provide a tidy and organized way to connect multiple wires, preventing tangled and cluttered wiring. This simplifies installation and maintenance, as well as improves the overall aesthetics of the electrical system.

2. Secure Connection: Terminal blocks provide a secure and reliable connection for electrical wires, preventing accidental disconnection and ensuring a continuous flow of power. This helps to reduce the risk of electrical faults and ensures the safety and reliability of the electrical system.

3. Flexibility and Reusability: Terminal blocks offer flexibility and reusability, allowing for easy reconfiguration and expansion of wiring as needed. This makes them suitable for applications where changes and modifications are common, such as industrial automation systems and control panels.

4. Time and Cost Savings: Terminal blocks help to streamline the wiring process, saving time and labor costs for installation and maintenance. They also reduce the need for specialized tools and expertise, making them a cost-effective solution for electrical connections.

5. Enhanced Safety: Terminal blocks provide a barrier between electrical connections, reducing the risk of accidental contact and short-circuiting. This enhances the overall safety of the electrical system and helps to comply with industry safety standards and regulations.