What Is The Difference Between Terminal Blocks And Terminal Blocks?

The main purpose of terminal blocks in electronics is to connect different components of a circuit. They are critical for the smooth operation of various electrical systems. In this article, we will discuss the difference between two types of terminal blocks, their usage, and applications in the industry. We will look at terminal blocks and their various types, as well as their differences, advantages, and disadvantages. This information will be valuable for technicians, engineers, and anyone interested in understanding the intricate details of electrical components.

Understanding Terminal Blocks

Terminal blocks, also known as connection terminals or terminal connector blocks, are modular, insulated blocks that secure two or more wires together. They are usually used to connect different components in control panels, distribution panels, and other industrial equipment. Terminal blocks come in various shapes, sizes, and materials like plastic, thermoplastic, and steel. They are widely used in automation, manufacturing, power distribution, and control systems. Terminal blocks are essential for organizing wires and cables and preventing electrical shorts and damage.

Terminal blocks are used to secure or terminate wires, providing a connection point for different electrical components. The primary function is to connect a wire to another wire or device through the use of conductive metal strips or screws. Terminal blocks are used in various industrial, commercial, and residential applications to connect electrical wiring and to facilitate the connection to control systems and other devices. They are useful for providing a secure, organized means of connecting various electrical components.

Types of Terminal Blocks

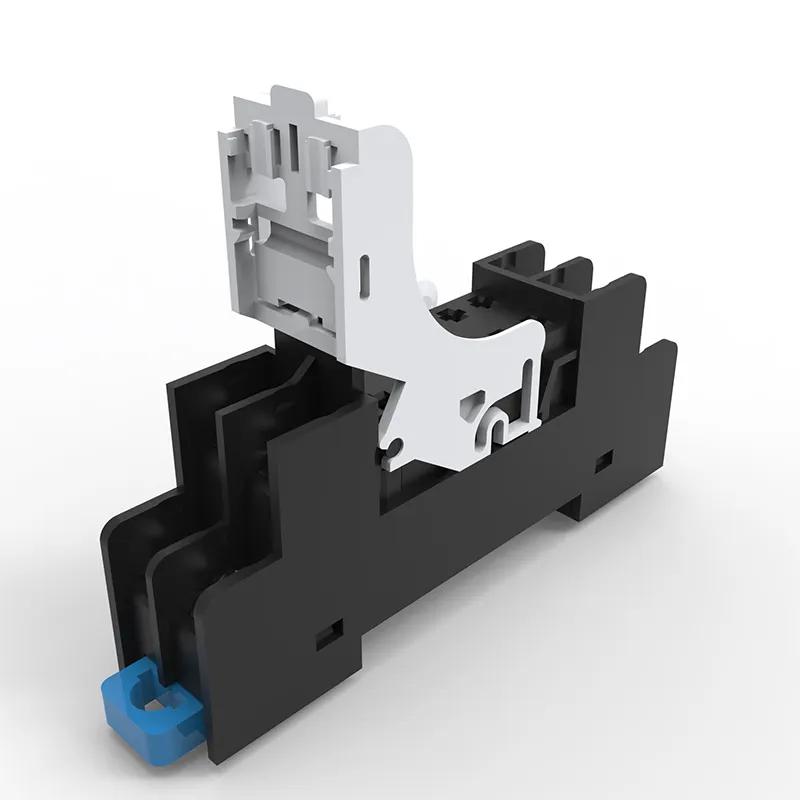

There are different types of terminal blocks available in the market, and each type has specific features and applications. Some common types include barrier terminal blocks, DIN rail terminal blocks, PCB terminal blocks, and pluggable terminal blocks. Barrier terminal blocks are used to interconnect two or more wires in industrial control applications, while DIN rail terminal blocks are designed to mount on DIN rails and are widely used in panel-building applications.

PCB terminal blocks are designed for mounting on printed circuit boards and are used in various electronic devices. Pluggable terminal blocks offer modular and flexible solutions for PCB connections and are commonly used in industrial automation. There are also other specialized terminal blocks such as power distribution blocks, feed-through terminal blocks, and fuse terminal blocks, each designed for specific applications and voltage ratings.

Advantages of Terminal Blocks

Terminal blocks offer several advantages over other wiring methods. They provide a secure and reliable means of connecting wires and cables, reducing the risk of loose connections or wiring errors. Terminal blocks also offer a clean and organized way of managing wires and cables, making it easier to troubleshoot and maintain electrical systems. They are also easy to install and reconfigure, providing flexibility in wiring layouts and component placement.

Terminal blocks also offer the advantage of modularity, allowing for easy replacement and expansion of components without having to rewire the entire system. They are available in various configurations to accommodate different wire sizes, number of connections, and power ratings. Additionally, terminal blocks provide a safer means of connecting wires, reducing the risk of electrical hazards and accidents. Overall, terminal blocks offer a cost-effective and efficient solution for connecting electrical components in various applications.

Understanding Terminal Blocks vs. Terminal Blocks

While the term "terminal blocks" is often used interchangeably, there are some key differences between them. Terminal blocks are used for connecting electrical wires or cables, providing a means of terminating or securing the wire to a component, whereas terminal blocks are specifically designed for low-voltage and signal applications. Terminal blocks are designed to handle higher currents and voltages and are used in power distribution and control systems. They offer a more robust construction and higher power ratings compared to terminal blocks.

Terminal blocks are designed to provide a secure and reliable connection for power-related applications, while terminal blocks are more suited for low-voltage and signal-level connections. Terminal blocks are often equipped with larger wire entry points, higher current ratings, and higher insulation voltage ratings. They are also designed to provide a more secure and durable connection for power-related applications. In contrast, terminal blocks are designed for smaller wire sizes and lower power ratings, making them suitable for signal and control circuits.

Applications of Terminal Blocks and Terminal Blocks

Terminal blocks are used in a wide range of applications, including industrial automation, machinery, control panels, power distribution, and HVAC systems. They are commonly used to connect components such as sensors, actuators, relays, contactors, and power supplies. Terminal blocks provide a simple and effective means of wiring and organizing electrical components. They are also used in residential and commercial wiring applications for connecting switches, outlets, and lighting fixtures.

Terminal blocks are widely used in control systems, PLCs, motor controls, and electrical panels. They are also used in power distribution applications for connecting circuit breakers, transformers, and other power-related components. Terminal blocks are essential for providing a secure and organized means of connecting larger wire sizes and handling higher currents and voltages. They are also used in commercial and industrial lighting applications for connecting ballasts, drivers, and lighting controls.

Conclusion

In conclusion, terminal blocks and terminal blocks are essential components for connecting electrical wires and cables in various applications. Terminal blocks provide a secure and organized means of connecting power-related components, while terminal blocks are designed for low-voltage and signal-level connections. Both types of terminal blocks offer unique advantages and features, making them suitable for different applications. Understanding the differences between terminal blocks and terminal blocks will help in selecting the right component for specific wiring and connection requirements. Whether in industrial automation, control systems, power distribution, or residential wiring, terminal blocks and terminal blocks play a critical role in providing a reliable and safe means of connecting electrical components.