Din Rail Double-layer Push-in Ground Terminal Block RPTTB1.5-PE for Automotive Premium RY-ELE

Characteristics

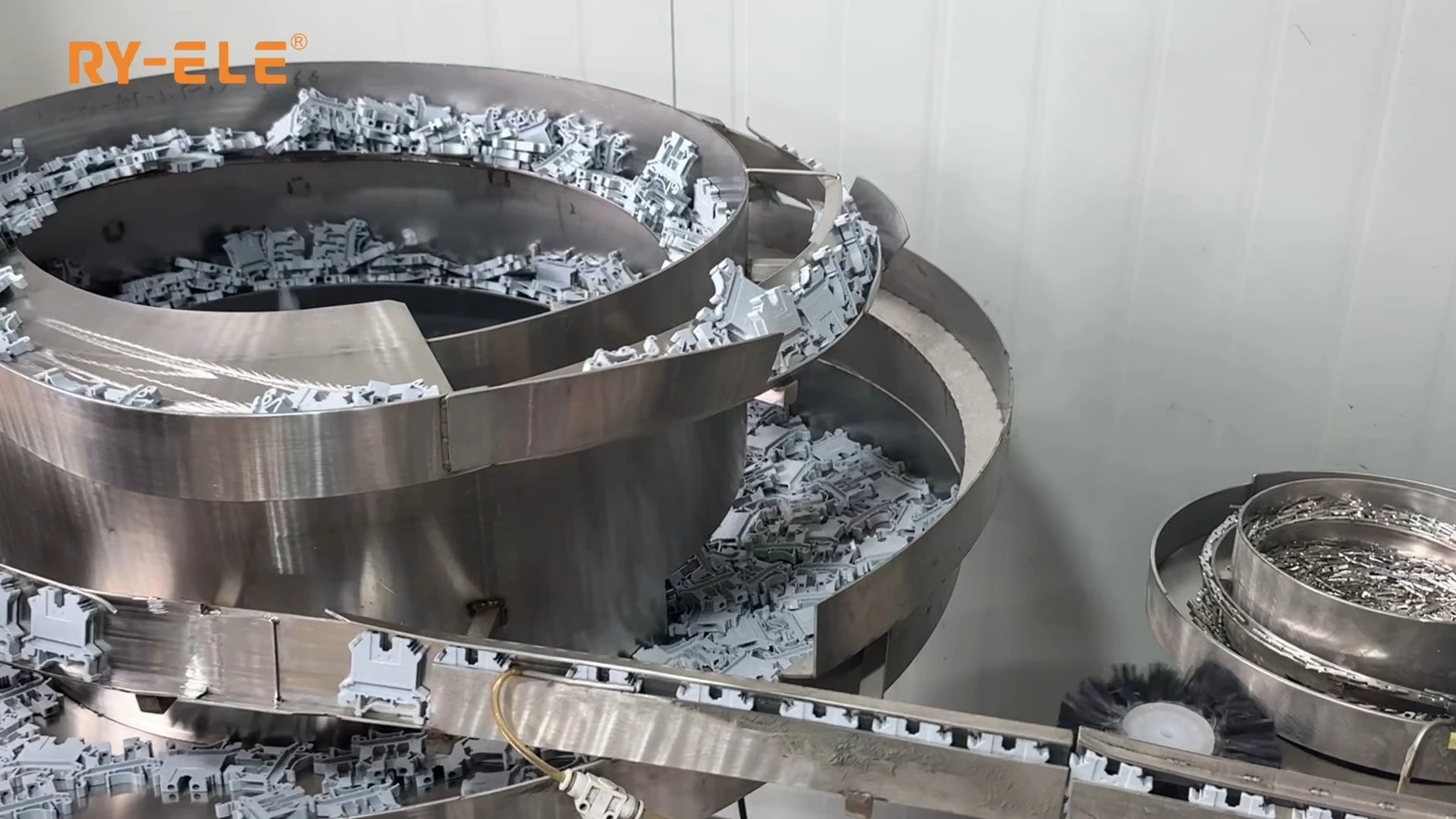

●Modular and flexible configuration

●Efficient connection and vibration-resistant design

●Wide voltage and multi-scenario compatibility

●Adaptability to harsh environments

●Easy Maintenance and Inspection

●Versatile Mounting Options

●Uniform Accessories

●High Electrical Performance

●Eco-Friendly and Sustainable

Product Advantages

why Choose Our Terminal Blocks?

Versatility: Suitable for a wide range of industrial and commercial applications.

Reliability: Engineered for durability and long-lasting performance.

Ease of Use: Designed with user-friendly features to simplify installation and maintenance.

Customization: Flexible configurations and accessories to meet your specific needs.

Upgrade your electrical systems with our high-quality terminal blocks, designed to deliver performance, reliability, and ease of use in every application.

Typical application scenarios

FAQ