How does a relay work on an AC and DC circuit?

Relays are versatile and essential components in both AC and DC circuits, used for a variety of applications ranging from switching high power loads to controlling small electronic devices. Understanding how relays work in both AC and DC circuits is crucial for anyone involved in electrical engineering, electronics, or even just curious about how everyday devices function. In this article, we will delve into the intricacies of relays and explore their function in both AC and DC circuits.

The Basics of Relays

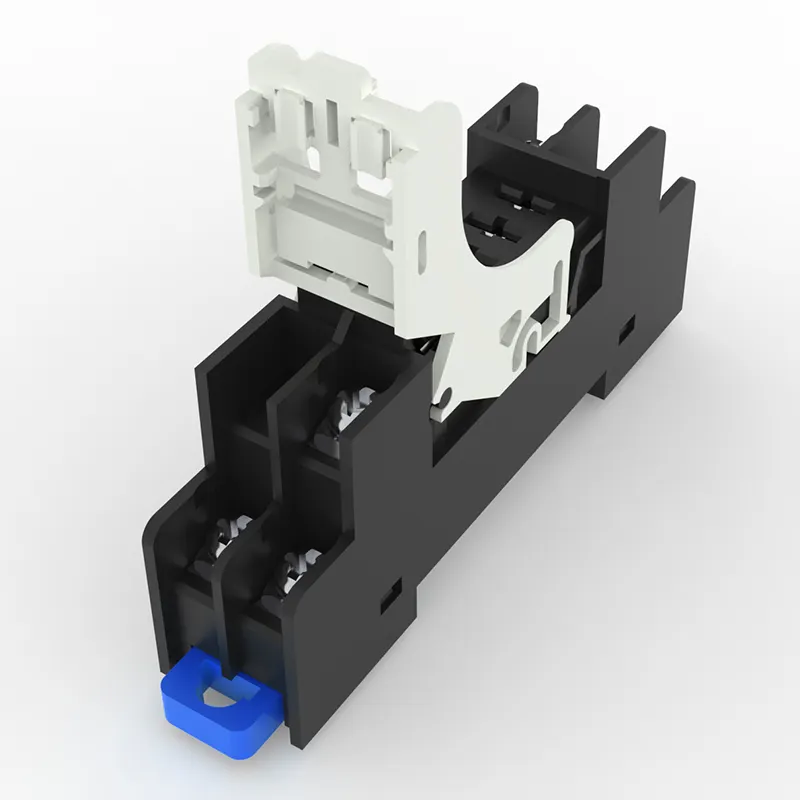

Relays are electromechanical switches that are activated by an electrical signal. They consist of a coil, an armature, a set of contacts, and sometimes a spring. When an electric current flows through the coil, it produces a magnetic field, causing the armature to move and close or open the contacts. The contacts are the actual switching mechanism of the relay, allowing it to control a separate circuit with a different voltage and current than the input signal. Relays can be categorized into different types based on their mode of operation, such as electromagnetic relays, solid-state relays, and thermal relays.

Relays are commonly used in applications where it is necessary to control a high-power circuit with a low-power signal, such as in automotive electrical systems, industrial control systems, and home automation. They are also widely used for safety and isolation purposes, as they can electrically isolate the control circuit from the load circuit.

Relays in AC Circuits

In an AC circuit, the alternating current causes the coil of the relay to create a magnetic field that continuously changes direction. This constant change in the magnetic field induces an alternating current in the armature, causing it to vibrate rapidly. As a result, the contacts of the relay switch back and forth at the same frequency as the AC signal. This rapid switching can lead to arcing and pitting of the contacts, which can reduce the reliability and lifespan of the relay.

To address the challenges posed by AC circuits, special AC relays are designed with features to minimize arcing, such as using contacts with a higher contact force and special contact materials. Additionally, an AC relay may incorporate a shading coil or a small copper ring to delay the opening of the contacts slightly after the coil is de-energized. This delay helps to reduce arcing and extend the life of the relay.

Relays in DC Circuits

In contrast to AC circuits, in a DC circuit, the current flows in only one direction, causing the coil of the relay to produce a steady magnetic field. This results in a constant force acting on the armature, leading to a smoother and more predictable operation of the relay. However, the lack of zero crossings in DC circuits can lead to a buildup of electrical chatter and oxidation on the contacts, which can affect the reliability of the relay.

To mitigate the effects of electrical chatter and oxidation, DC relays are often designed with features such as arc quenching magnets and contact materials that are specifically suited for DC circuits. Furthermore, some DC relays employ a diode or a freewheeling diode across the coil to suppress the back electromotive force generated when the coil is de-energized, preventing voltage spikes that can damage sensitive electronic components.

Comparison of AC and DC Relay Operation

The differences in the behavior of relays in AC and DC circuits are primarily due to the nature of the electrical signals and the challenges associated with each type of circuit. In AC circuits, the rapid changes in the magnetic field and the resultant arcing and pitting of contacts are key considerations, while in DC circuits, the issues of electrical chatter and oxidation of contacts are more prevalent.

In general, when selecting a relay for a specific application, it is important to consider the characteristics of the circuit, the type of load being controlled, and the environmental conditions that the relay will be subjected to. Additionally, understanding the nuances of relay operation in both AC and DC circuits can help in identifying the most appropriate relay for a given application.

Applications of Relays in AC and DC Circuits

Relays find wide-ranging applications in both AC and DC circuits due to their versatility and ability to interface between different voltage and current levels. In AC circuits, relays are commonly used for controlling large appliances, HVAC systems, and lighting systems. They are also employed in motor control, power distribution, and safety interlocks in industrial equipment.

In DC circuits, relays are utilized in automotive electronics, battery management systems, solar energy systems, and telecommunication equipment. They are also an integral part of electronic devices, providing functions such as signal switching, current protection, and voltage regulation.

In both AC and DC circuits, relays are crucial for implementing fail-safe systems, where the relay can be used to disconnect a load in the event of a fault or abnormal condition. For example, relays are often used in control panels to monitor the status of equipment and to initiate protective actions if necessary.

Conclusion

Relays are fundamental components in electrical and electronic systems, providing a means to control and isolate circuits with different voltage and current levels. Their operation in AC and DC circuits presents unique challenges and considerations, necessitating the use of specialized relays designed to address the specific characteristics of each type of circuit.

Understanding how relays work in both AC and DC circuits is essential for engineers, technicians, and hobbyists alike, as it enables the selection of the most suitable relay for a given application and ensures the reliable and efficient operation of the electrical and electronic systems. Whether it is for controlling a motor, switching a lighting circuit, or implementing safety interlocks, relays play a vital role in modern technology and continue to be indispensable in a wide array of applications.