How does the latching mechanism in magnetic latching relays ensure reliable and stable operation?

The latching mechanism in magnetic latching relays is a critical component that ensures the reliable and stable operation of these devices. Understanding how this mechanism works is essential for anyone working with these relays or considering using them in their projects. In this article, we will explore the inner workings of the latching mechanism in magnetic latching relays and how it contributes to the overall performance of the relay.

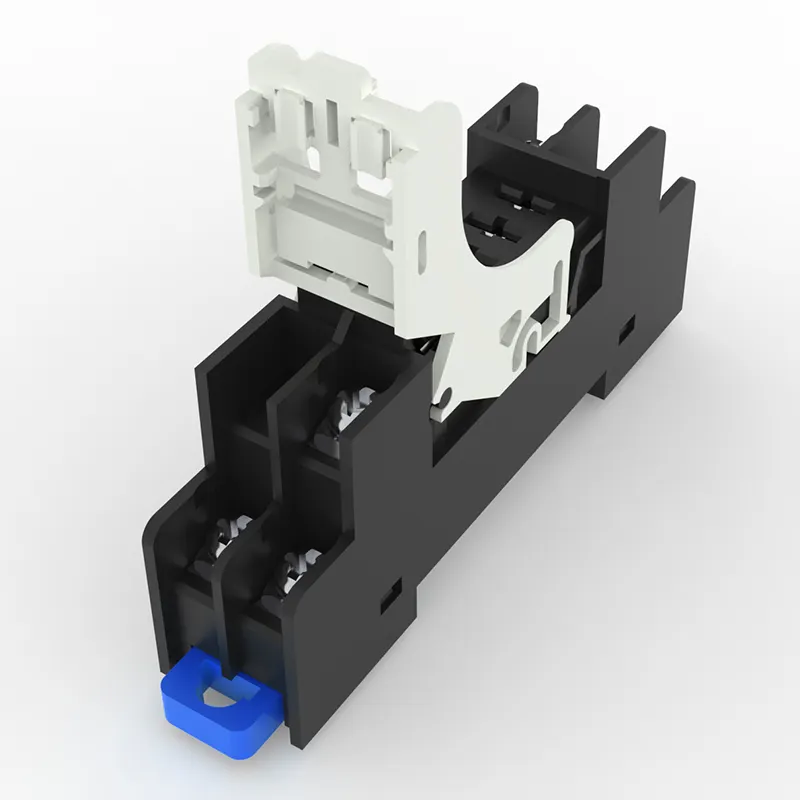

The Basics of Magnetic Latching Relays

Magnetic latching relays are a type of relay that uses a permanent magnet to maintain the contact position without the need for continuous power. This design makes them particularly useful in applications where power consumption is a concern, such as in battery-operated devices or energy-efficient systems. The latching mechanism in these relays is what enables them to maintain their state even when power is removed, making them reliable and efficient.

When the coil of a magnetic latching relay is energized, it creates a magnetic field that causes the movable armature to move and make contact with the stationary contacts. Once this contact is made, the permanent magnet inside the relay holds the armature in place, maintaining the contact position even after the coil is de-energized. This unique design allows magnetic latching relays to remain in their last switched state indefinitely, until the coil is energized again to change the position of the contacts.

How the Latching Mechanism Works

The latching mechanism in a magnetic latching relay consists of several key components working together to ensure reliable and stable operation. At the heart of this mechanism is the permanent magnet, which is responsible for holding the armature in place once the contacts are made. This magnet is carefully positioned and engineered to provide the right amount of force to maintain the contact position without requiring excessive power.

In addition to the permanent magnet, the latching mechanism also includes a spring or other mechanical components that assist in holding the armature in place. These components are carefully designed to provide the necessary amount of force to keep the contacts stable, while also allowing for the armature to be easily released when the coil is energized again. This balance of forces is essential for the proper operation of the latching mechanism.

Advantages of Magnetic Latching Relays

The latching mechanism in magnetic latching relays offers several advantages over other types of relays. One of the most significant advantages is the ability to maintain the contact position without continuous power, which reduces energy consumption and increases overall efficiency. This makes magnetic latching relays ideal for applications where power is limited or where energy efficiency is a priority.

Another advantage of the latching mechanism in these relays is the ability to withstand shock and vibration without affecting the contact position. The permanent magnet and other mechanical components work together to ensure that the contacts remain stable even in harsh operating conditions, making magnetic latching relays suitable for use in a wide range of environments.

In addition, the latching mechanism in magnetic latching relays offers low acoustic noise during operation, making them suitable for use in noise-sensitive applications. The absence of continuous humming or buzzing associated with traditional relays makes magnetic latching relays a preferred choice in environments where noise levels must be kept to a minimum.

Applications of Magnetic Latching Relays

The reliable and stable operation of magnetic latching relays makes them well-suited for a variety of applications across different industries. One common application is in power meters, where these relays are used for switching different voltage potentials. The ability to maintain contact position without continuous power makes magnetic latching relays ideal for this application, as it reduces energy consumption and heat generation.

Another application of magnetic latching relays is in industrial control systems, where these relays are used for switching and controlling various devices and equipment. The stable and reliable operation of these relays ensures that the control system functions as intended, without the risk of unintended contact position changes due to power fluctuations or disturbances.

Magnetic latching relays are also used in automotive applications, where they are used for switching various circuits in vehicles. The ability to withstand shock and vibration, as well as the low acoustic noise during operation, makes these relays a preferred choice in automotive electronics where reliability and durability are essential.

Challenges and Considerations

While magnetic latching relays offer several advantages, there are also some challenges and considerations to keep in mind when using these relays. One potential challenge is the need for careful design and engineering to ensure that the latching mechanism functions as intended. The positioning of the permanent magnet, the design of the mechanical components, and the overall construction of the relay require careful attention to detail to ensure reliable and stable operation.

Another consideration when using magnetic latching relays is the potential for residual magnetism to affect the operation of the relay. Over time, the permanent magnet inside the relay may retain some degree of magnetism, which can potentially interfere with the proper release of the armature when the coil is energized. Designing the relay to mitigate this effect and ensure consistent operation over the long term is an important consideration for engineers and designers.

In addition, the size and weight of magnetic latching relays can be a consideration, particularly in applications where space and weight are at a premium. While advancements in materials and design have allowed for smaller and lighter relays, these factors may still need to be carefully considered in certain applications to ensure the optimal performance of the relay.

Conclusión

The latching mechanism in magnetic latching relays is a critical component that ensures the reliable and stable operation of these devices. By carefully balancing the forces exerted by the permanent magnet and other mechanical components, these relays can maintain contact position without continuous power, withstand shock and vibration, and provide low acoustic noise during operation. Understanding the inner workings of the latching mechanism is essential for anyone working with magnetic latching relays, as it allows for the proper design and application of these relays in a wide range of industries and applications.