How to select the right solid state relay ?

Solid state relays (SSRs) are essential components in modern electrical systems. They are used to control high-power loads with a low-power control signal, offering advantages such as long life, noiseless operation, and high switching speed. With the widespread use of SSRs in various applications, selecting the right solid state relay has become increasingly important. In this article, we will discuss the key factors to consider when choosing an SSR to ensure optimal performance and reliability.

Understanding Solid State Relays

Solid state relays are electronic switches that rely on semiconductors to perform the switching operation, unlike electromechanical relays that use mechanical contacts. They consist of a control input, an output, and a semiconductor switching device such as a thyristor or a triac. When a control signal is applied, the semiconductor device turns on, allowing current to flow through the output terminals. SSRs are available in various configurations, including single-pole single-throw (SPST), single-pole double-throw (SPDT), and others, to suit different application requirements.

In addition to their compact size and long life, solid state relays offer other advantages over electromechanical relays, such as silent operation, high resistance to shock and vibration, and the absence of contacts that can wear out over time. These features make SSRs suitable for applications in industrial control systems, HVAC equipment, power distribution, and many other fields.

Key Considerations for Selecting the Right Solid State Relay

When selecting a solid state relay for a particular application, it is important to consider several key factors to ensure that the chosen relay meets the performance and reliability requirements. The following are the main considerations to keep in mind when choosing an SSR.

Load Voltage and Current Ratings

One of the most critical factors to consider when selecting a solid state relay is the load voltage and current ratings. It is essential to choose an SSR with voltage and current ratings that are compatible with the requirements of the load and the control system. The SSR's voltage rating should be at least as high as the maximum voltage that the load will experience, while the current rating should be sufficient to handle the maximum load current without exceeding the relay's specifications.

When selecting an SSR for resistive loads such as heaters or lamps, the current rating is typically the primary consideration. However, for inductive or capacitive loads, the SSR's ability to handle the inrush current and the power factor of the load should also be taken into account. It is crucial to choose a solid state relay with adequate voltage and current ratings to ensure safe and reliable operation in the intended application.

Control Input Voltage and Current

Another important consideration when selecting a solid state relay is the control input voltage and current. The control input is the signal that activates the SSR, and it is crucial to choose a relay that is compatible with the control logic and voltage levels of the system. SSRs are available with various control input voltage options, such as 3-32VDC, 5VDC, 12VDC, or 24VDC, to accommodate different control signal sources.

In addition to the control input voltage, the control current required to activate the SSR should also be considered. It is essential to choose a relay with a control input current that is within the capability of the control signal source, whether it is a microcontroller, PLC, or other devices. Choosing an SSR with the correct control input voltage and current ensures seamless integration into the control system and reliable operation of the load.

Switching Speed and Response Time

The switching speed and response time of a solid state relay are crucial factors to consider, especially in applications that require precise timing and fast switching. The switching speed determines how quickly the SSR can turn on and off in response to the control signal, while the response time is the time it takes for the relay to reach full conduction or turn off after receiving the control input.

For applications that require rapid cycling or high-frequency switching, such as motor control or power inverters, it is essential to choose an SSR with a fast switching speed and response time. On the other hand, for applications that involve slower and less frequent switching, such as heating control or lighting systems, the switching speed and response time may be less critical. Selecting a solid state relay with the appropriate switching characteristics ensures that the relay can meet the timing requirements of the application and maintain stable operation.

Environmental and Mounting Considerations

The environmental and mounting conditions of the application also play a significant role in the selection of a solid state relay. Depending on the specific application, the SSR may be subjected to harsh environmental conditions such as high temperature, humidity, or exposure to contaminants. In such cases, it is important to choose a relay with a rugged construction and suitable environmental ratings to ensure reliable operation in challenging environments.

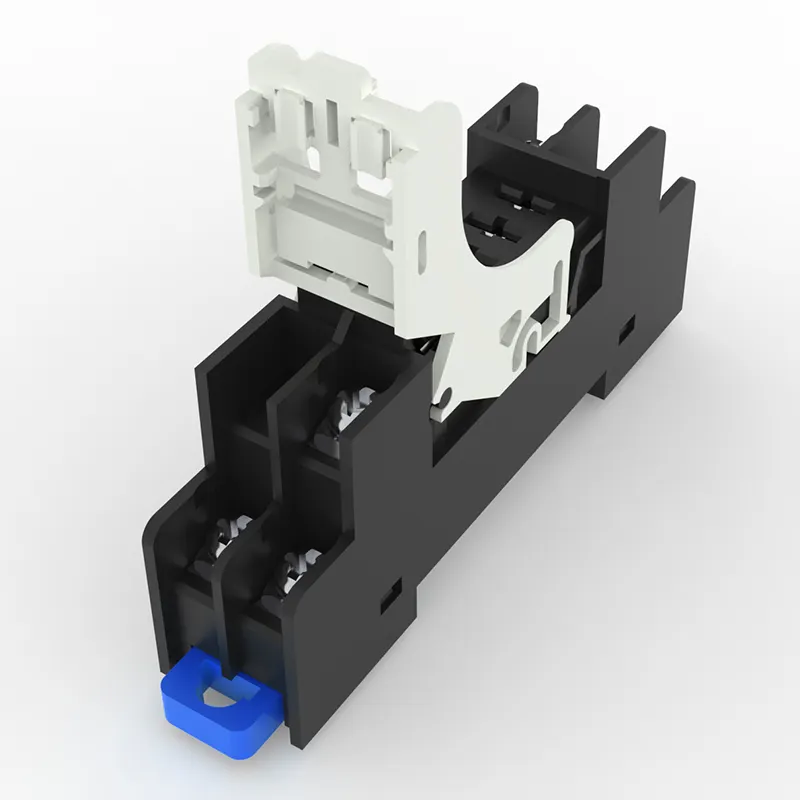

Furthermore, the mounting method and configuration of the SSR should be compatible with the installation requirements of the application. Solid state relays are available in various mounting styles, such as panel mount, DIN rail mount, and PCB mount, to accommodate different installation needs. The chosen relay should have a mounting configuration that allows for easy and secure installation in the designated location, with proper consideration for factors such as heat dissipation and accessibility for maintenance.

Load Compatibility and Protection Features

When selecting a solid state relay, it is crucial to consider the compatibility of the relay with the specific type of load it will be controlling. SSRs are available with different output configurations, such as zero-crossing and random turn-on, to match the characteristics of resistive, inductive, or capacitive loads. Choosing a relay with the appropriate output configuration ensures smooth and reliable operation of the load without causing excessive voltage spikes, inrush currents, or other detrimental effects.

In addition to load compatibility, it is important to consider the protection features provided by the solid state relay. Some SSRs offer built-in protection against overcurrent, overtemperature, and short-circuit conditions, which can help safeguard the load and the relay itself from damage. Selecting a relay with the necessary protection features can enhance the safety and reliability of the overall system, especially in applications where the load may be exposed to external disturbances or fault conditions.

Summary

Selecting the right solid state relay is essential for ensuring optimal performance and reliability in electrical control systems and other applications. When choosing an SSR, it is important to consider factors such as load voltage and current ratings, control input requirements, switching speed and response time, environmental and mounting considerations, load compatibility, and protection features. By carefully evaluating these factors and selecting a solid state relay that meets the specific requirements of the application, engineers and system designers can ensure the successful integration and operation of the relay in their designs. With the increasing availability and diversity of SSRs in the market, it is essential to understand the key considerations and take a systematic approach to selecting the most suitable relay for each application.