Relay: The heart of electrical control, driving the precise pulse of industrial automation

The heart of electrical control, driving the precise pulse of industrial automation

Relay: An Introduction

Relays are essential components in electrical control systems, providing the precise pulse that drives industrial automation. These small devices play a significant role in controlling larger electrical systems, allowing for the seamless operation of manufacturing processes, power distribution, and other industrial applications. In this article, we will explore the inner workings of relays, their importance in industrial automation, and the different types of relays available in the market today.

The Function of Relays in Industrial Automation

Industrial automation relies heavily on the precise control of electrical systems, and relays are at the heart of this control. At its core, a relay is an electromagnetic switch that allows a low-voltage control signal to activate or deactivate a high-voltage circuit. This function is crucial in industrial settings, where the need for precision and reliability is paramount. By providing a safe and efficient way to control high-voltage circuits using low-voltage signals, relays serve as the backbone of industrial automation.

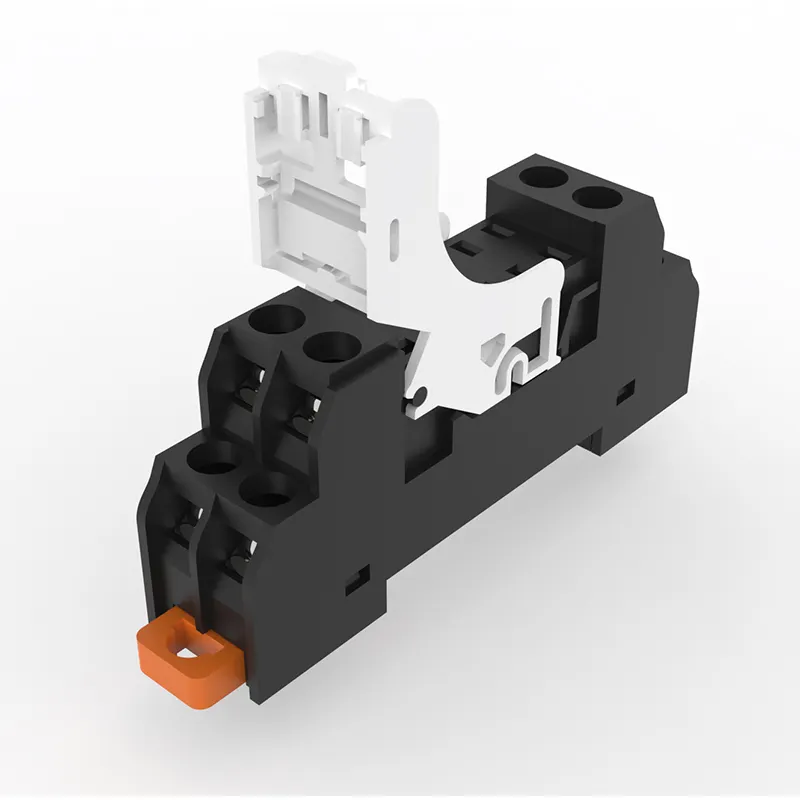

Relays come in various forms, each designed for specific applications. Electromechanical relays use a coil and armature to control the switching of contacts, while solid-state relays rely on semiconductor devices for the same purpose. Both types have their advantages and limitations, making them suitable for different industrial automation scenarios.

The Importance of Choosing the Right Relay

Selecting the right relay for an industrial automation application is crucial to ensuring the smooth and reliable operation of electrical systems. Various factors must be considered when choosing a relay, including the voltage and current ratings of the circuit, the type of load being controlled, and the environmental conditions in which the relay will operate. Failure to select the appropriate relay can result in system malfunction, downtime, and potential safety hazards.

When it comes to industrial automation, reliability is paramount. Relays must be able to withstand the rigors of continuous operation in harsh industrial environments while maintaining precision and accuracy. Additionally, the fast response times and low power consumption of relays are essential for optimizing the performance of industrial automation systems.

Types of Relays in Industrial Automation

In industrial automation, different types of relays are used to suit various application requirements. Electromechanical relays, also known as mechanical relays, are the traditional choice for many industrial applications. These relays are reliable and robust, making them suitable for controlling heavy loads and operating in harsh environments. However, electromechanical relays have moving parts that can wear out over time, leading to potential maintenance issues.

Solid-state relays, on the other hand, offer several advantages over their electromechanical counterparts. These relays use semiconductor devices to switch the load, resulting in faster response times, silent operation, and longer lifespan. Solid-state relays are also immune to mechanical wear and are ideal for applications that require high switching frequencies. However, they are more sensitive to overcurrent and overvoltage conditions, requiring additional protection measures to ensure their longevity.

The Evolution of Relay Technology in Industrial Automation

Over the years, relay technology has advanced significantly, driven by the increasing demands of industrial automation. Modern relays are designed to offer enhanced performance, reliability, and flexibility, allowing for more sophisticated control of electrical systems in industrial settings. With the advent of digital communication protocols and smart technologies, relay manufacturers have introduced intelligent relays that enable remote monitoring, diagnostics, and predictive maintenance capabilities.

The integration of relay technology with programmable logic controllers (PLCs) and industrial control systems (ICS) has further enhanced the capabilities of relays in industrial automation. These advanced control systems provide centralized management of relays, enabling seamless integration with other industrial devices and equipment. As a result, industrial operators can achieve higher levels of efficiency, safety, and productivity in their automation processes.

The Future of Relays in Industrial Automation

As industrial automation continues to evolve, the role of relays will remain pivotal in driving the precise pulse of electrical control. The ongoing advancements in relay technology, such as the development of miniaturized relays, solid-state relays, and intelligent relays, will further enhance the capabilities of industrial automation systems. Moreover, as the demand for energy-efficient and environmentally friendly solutions grows, relays will play a crucial role in optimizing the performance of electrical systems in industrial settings.

In conclusion, relays are the heart of electrical control, driving the precise pulse of industrial automation. These small yet essential components enable the seamless operation and precise control of industrial electrical systems, serving as the backbone of industrial automation. With the continuous advancements in relay technology, the future looks promising for the role of relays in industrial automation. As industrial processes become more complex and demanding, relays will continue to play a vital role in ensuring the efficiency, safety, and reliability of industrial automation systems.

The above article discusses the crucial role of relay technology in industrial automation, highlighting its function, importance, types, evolution, and future prospects. It provides valuable insights into the significance of relays in driving the precise pulse of electrical control, paving the way for more efficient and reliable industrial automation systems.