What Does a Push Button Switch Do?

مقدمه:

Have you ever wondered what exactly a push button switch does? Push button switches are a common feature in many electronic devices and machinery, but their function and importance are often overlooked. In this article, we will explore the ins and outs of push button switches, including their various types, applications, and how they work. Whether you're an electronics enthusiast or simply curious about the inner workings of everyday technology, this article will provide you with a comprehensive understanding of push button switches and their role in modern electronics.

Types of Push Button Switches

Push Button Switch Basics

Push button switches are a type of mechanical switch that is typically used to control the flow of electricity in a circuit. They are commonly found in a wide range of electronic devices, from household appliances to industrial machinery. Push button switches are designed to be actuated by pressing the button, which then completes or interrupts the electrical circuit. This action can be used to turn a device on or off, control the speed or direction of a motor, or initiate a specific function within a larger system.

There are several different types of push button switches, each with its own unique characteristics and applications. Momentary push button switches, for example, are designed to only remain in the actuated state while the button is being pressed. As soon as the pressure is released, the switch returns to its original position and the circuit is broken. This makes momentary push button switches ideal for applications where temporary or intermittent control is required, such as in the operation of a doorbell or a machine start button.

Other types of push button switches include latching push button switches, which remain in the actuated state until they are manually reset, and illuminated push button switches, which feature built-in LED indicators for visual feedback. Each type of push button switch is designed to meet specific requirements and can be selected based on factors such as the application, operating environment, and user interface design.

Applications of Push Button Switches

لوازم الکترونیکی مصرفی

Push button switches are ubiquitous in consumer electronics, where they are commonly used as power switches, mode selectors, and function triggers. In smartphones, for example, push button switches are used to control the device's power state, adjust the volume, and activate various features such as the camera or voice assistant. In gaming consoles, push button switches are used as controller buttons to provide input for gameplay actions. The compact size and tactile feedback of push button switches make them an ideal interface for user interaction in consumer electronics, offering a satisfying click or tactile response when pressed.

In household appliances, push button switches are used for tasks such as controlling the temperature and operation mode of air conditioners, activating the start and stop functions of washing machines, and programming the cooking settings of microwave ovens. The versatility and reliability of push button switches make them an essential component in the user interface design of modern consumer electronics, contributing to a seamless and intuitive user experience.

Industrial Control Systems

In industrial settings, push button switches play a critical role in controlling machinery, equipment, and production processes. They are often integrated into control panels, control stations, and machine enclosures to provide operators with tactile and visual feedback for initiating, stopping, and monitoring specific functions. Push button switches used in industrial control systems are designed to withstand harsh operating conditions, such as extreme temperatures, moisture, and mechanical impact, ensuring reliable performance in demanding environments.

Industrial-grade push button switches are available in a variety of configurations, including emergency stop switches, start/stop switches, selector switches, and reset switches. These switches are used to enable safe and efficient operation of equipment in manufacturing facilities, production lines, and processing plants. With options for custom labeling, color-coding, and protection ratings, push button switches can be tailored to meet the specific requirements of industrial control applications, enhancing operator safety and productivity.

Working Principle of Push Button Switches

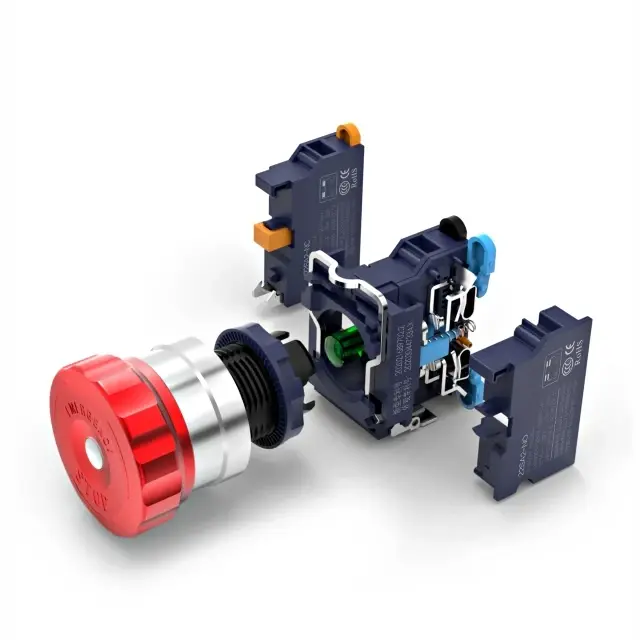

Contact Mechanism

The fundamental mechanism of a push button switch relies on a set of electrical contacts that make or break the circuit when the button is actuated. Inside the switch housing, there are typically two or more metal contacts that are brought into contact by the movement of the button. When the contacts touch, the electrical circuit is completed, allowing current to flow through the switch and activate the connected device or function. Conversely, when the button is released, the contacts separate, breaking the circuit and interrupting the flow of current.

Depending on the design of the push button switch, the contact mechanism may include silver or gold-plated contacts to improve electrical conductivity and reduce contact resistance. Some switches also incorporate self-cleaning contacts to prevent oxidation and buildup of debris over time, ensuring consistent performance and longevity. The contact arrangement of push button switches can vary, including configurations such as normally open (NO), normally closed (NC), and momentary (SPST) contacts, providing versatile options for different control applications.

Actuation Methods

Push button switches can be actuated using various methods, with the most common being the physical depression of the button by the user. This action causes the button to move internally and bring the contact points together, allowing current to flow. In some cases, push button switches may feature a spring-loaded mechanism that enables the button to return to its original position when released, offering tactile feedback and audible click sound. For applications requiring extended actuation or remote control, push button switches can also be interfaced with external actuation devices, such as levers, plungers, or pneumatic cylinders.

In addition to manual actuation, push button switches can be integrated with electronic control systems to enable digital or remote operation. This allows the switches to be activated by signals from microcontrollers, relays, or other electronic devices, offering programmable and automated control capabilities. Electronic actuation methods provide precise timing, sequencing, and coordination of multiple push button switches within complex systems, making them suitable for applications such as industrial automation, robotics, and smart home technology.

Summary:

In conclusion, push button switches are an essential component in modern electronics, serving a wide range of applications across industries and consumer products. Whether as a simple power switch in a household appliance or as a critical control element in industrial machinery, push button switches provide reliable and intuitive user interaction. Understanding the types, applications, and working principles of push button switches is crucial for designing and implementing effective control systems and electronic devices. By exploring the intricacies of push button switches, we gain insight into the fundamental technology that powers our everyday interactions with electronic devices and machinery.