What Is A Terminal Block? | Significance And Types - News

Terminal blocks are an essential component of many electrical systems. They are used to secure and distribute electrical connections and provide a convenient way to connect individual electrical wires. They come in various types and sizes and have different uses in electrical engineering and automation. In this article, we will explore the significance of terminal blocks and the different types available in the market.

The Significance of Terminal Blocks

Terminal blocks play a crucial role in electrical systems. They provide a secure and reliable way to connect electrical wires, allowing for easy installation, maintenance, and troubleshooting. In addition to creating a secure connection, terminal blocks also help in organizing and labeling the wires, making it easier to identify and trace them when needed. Furthermore, terminal blocks can be easily replaced or reconfigured, making them versatile and cost-effective solutions for electrical connections.

Types of Terminal Blocks

There are several types of terminal blocks available, each designed for specific applications and environments.

1. Barrier Terminal Blocks

Barrier terminal blocks are designed to provide a secure and insulated connection for electrical wires. They feature a plastic or metal barrier that separates each connection point, providing protection against accidental contact and short circuits. These terminal blocks are commonly used in industrial and automotive applications where safety and reliability are crucial.

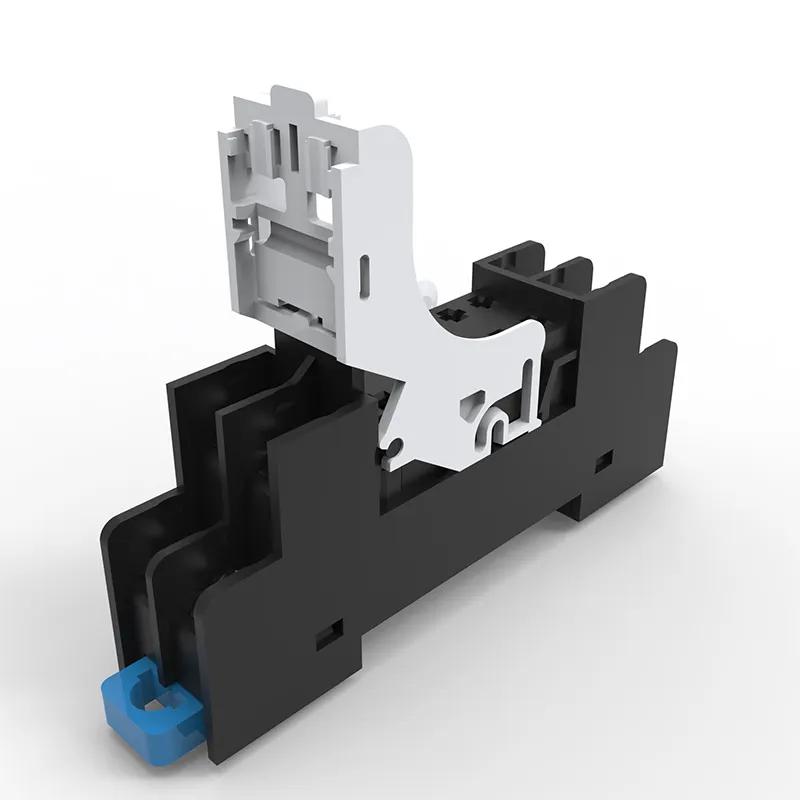

2. Din Rail Mounted Terminal Blocks

Din rail mounted terminal blocks are designed to be mounted on standard din rails, making them ideal for use in control panels and industrial automation systems. They are available in various configurations, including feed-through, ground, and disconnect types, providing flexibility and convenience for wiring and installation.

3. PCB Mounted Terminal Blocks

PCB mounted terminal blocks are designed to be directly mounted onto printed circuit boards, providing a convenient and space-saving solution for connecting electrical wires to PCBs. They come in different pitches and styles, such as rising clamp, screwless, and spring cage, catering to various PCB design requirements.

4. Pluggable Terminal Blocks

Pluggable terminal blocks feature a detachable connector that allows for quick and easy installation and replacement of electrical wires. They are commonly used in applications where frequent wiring changes or maintenance are anticipated, such as in test and measurement equipment, control cabinets, and industrial machinery.

5. Power Distribution Terminal Blocks

Power distribution terminal blocks are designed to handle high current and voltage levels, making them suitable for power distribution and management in industrial and commercial settings. They come with features such as multiple connection points, fuse holders, and disconnect switches, providing a reliable and flexible solution for power distribution applications.

How to Choose the Right Terminal Block

When selecting a terminal block for a specific application, several factors need to be considered to ensure the optimal performance and safety of the electrical system.

One critical factor is the electrical specifications, including current and voltage ratings, wire sizes, and temperature requirements. It is essential to choose a terminal block that can accommodate the electrical load and environmental conditions of the application.

Another consideration is the type of connection, such as screw clamp, spring clamp, or push-in, based on the application requirements and the convenience of wiring and maintenance.

Additionally, the mounting method, size, and material of the terminal block should also be evaluated to ensure compatibility with the installation environment and the mechanical strength required for the application.

Installation and Maintenance of Terminal Blocks

Proper installation and maintenance of terminal blocks are essential to ensure the safety and reliability of electrical connections. It is crucial to follow the manufacturer's instructions and industry standards when installing terminal blocks, including tightening torque specifications, wire stripping length, and insulation requirements.

Regular inspection and maintenance of terminal blocks are also necessary to prevent loose connections, corrosion, and other potential issues that can compromise the integrity of the electrical system. This includes checking for signs of overheating, tightening of terminal screws, and cleaning of the terminal block surfaces to remove dust and debris.

Innovations in Terminal Block Technology

Advancements in terminal block technology have led to the development of innovative features and capabilities that enhance the performance and convenience of electrical connections. Some of the latest innovations include integrated electronics for monitoring and control, pluggable connectors for modular wiring systems, and tool-less installation designs for quick and easy wiring. These innovations cater to the evolving needs of modern electrical systems, providing efficient and reliable solutions for various applications.

In conclusion, terminal blocks are essential components in electrical systems, providing secure and reliable connections for electrical wires. Understanding the significance and types of terminal blocks is crucial to selecting the right solution for specific applications. By considering the electrical specifications, installation requirements, and technological innovations, engineers and installers can make informed decisions to ensure the optimal performance and safety of electrical connections.