What is the purpose of an emergency stop button?

In industrial and manufacturing settings, safety is paramount. One critical safety feature that is installed in many machines and equipment is the emergency stop button. This simple yet essential device plays a crucial role in preventing accidents and ensuring the well-being of workers. In this article, we will explore the purpose of an emergency stop button and its significance in safeguarding personnel and equipment.

Understanding the Function of an Emergency Stop Button

An emergency stop button, also known as an e-stop or emergency stop switch, is a safety mechanism designed to quickly shut down machinery or equipment in emergency situations. When activated, the e-stop button interrupts the power supply to the machine, bringing it to an immediate stop. This rapid cessation of operations can help prevent accidents, injuries, and damage to the equipment.

The primary function of an emergency stop button is to provide a means for operators or nearby personnel to rapidly and easily shut down a machine if an unexpected hazard or dangerous situation arises. This could include instances such as entanglement, electrical malfunctions, structural failures, or any other scenario where there is an imminent risk to individuals or the equipment itself.

When an emergency occurs, time is of the essence, and the ability to swiftly halt the operation of a machine can mean the difference between a minor incident and a catastrophic event. The installation of emergency stop buttons on machinery is a proactive safety measure that helps to mitigate the potential harm that can result from unexpected emergencies.

The Importance of Emergency Stop Buttons in Industrial Settings

In industrial and manufacturing environments, the presence of heavy machinery, complex equipment, and high-powered tools can pose significant risks to workers and operators. The movement of heavy materials, the operation of intricate systems, and the use of sharp or fast-moving components all contribute to the potential for accidents and injuries.

The inclusion of emergency stop buttons in industrial machinery is a critical factor in ensuring workplace safety. By providing a readily accessible means to rapidly stop the operation of equipment, e-stop buttons empower workers to take quick action in the event of an emergency.

Furthermore, the presence of emergency stop buttons also addresses regulatory requirements and industry standards for safety. Regulatory agencies and governing bodies often mandate the inclusion of safety features such as emergency stop buttons in industrial equipment to protect the well-being of workers and minimize the risk of workplace accidents.

From a broader perspective, the importance of emergency stop buttons in industrial settings extends beyond individual worker safety. These devices also play a role in safeguarding the integrity of the equipment and preventing costly damage or downtime that can result from accidents or malfunctions.

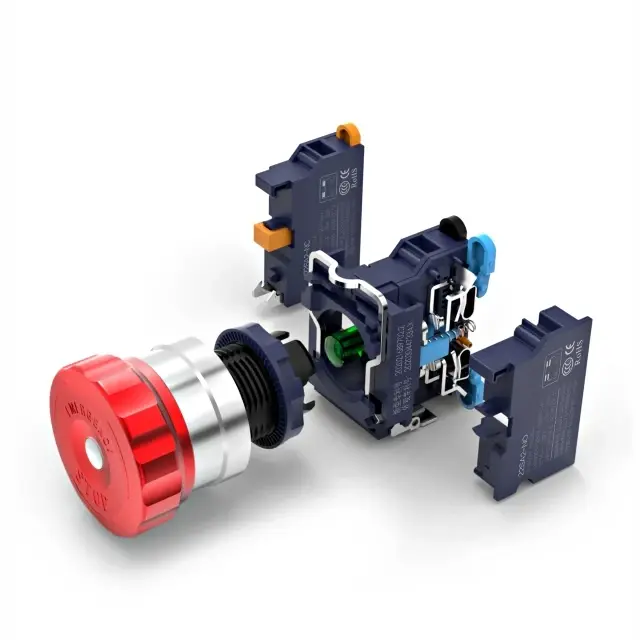

Design and Placement of Emergency Stop Buttons

The effectiveness of an emergency stop button hinges on its design and placement within the workspace. The button itself should be highly visible and easily accessible, allowing for immediate activation in the event of an emergency. The color and shape of e-stop buttons are often standardized to enhance recognition and ensure that they can be easily identified, even in high-stress situations.

Red is the most commonly used color for emergency stop buttons, as it is universally associated with danger and can be quickly distinguished from other controls or switches. Additionally, the button is typically designed to be large and prominent, making it easy to locate and operate, even under duress.

When it comes to the placement of emergency stop buttons, the goal is to ensure that they are within arm's reach of the operator or any individual working in the vicinity of the machinery. This may involve installing multiple e-stop buttons at various points around the equipment to ensure comprehensive coverage and quick access from different locations.

Careful consideration is also given to the integration of emergency stop buttons into the overall machine control system. These buttons are often wired in such a way that activating any one of them will immediately cut power to the entire machine, effectively stopping all moving parts and bringing operations to a swift halt.

Training and Awareness for Effective Use of Emergency Stop Buttons

While the presence of emergency stop buttons is crucial, their effectiveness is contingent upon the knowledge and readiness of personnel to utilize them in emergency situations. Proper training and education on the function and purpose of e-stop buttons are essential components of a comprehensive safety program in industrial settings.

Operators, maintenance personnel, and other workers who interact with machinery should receive thorough training on the location, operation, and significance of emergency stop buttons. This training should encompass a range of potential emergency scenarios and emphasize the importance of quick action and decisive use of the e-stop button when necessary.

In addition to training, workplace awareness and a culture of safety are instrumental in ensuring that emergency stop buttons serve their intended purpose. Regular safety briefings, signage, and reminders about the location and use of e-stop buttons can help reinforce the importance of these devices and promote a proactive mindset towards safety among employees.

Moreover, proper maintenance and periodic testing of emergency stop buttons are critical to their reliability. Routine inspections and checks should be conducted to verify that the buttons are functioning correctly and that they will effectively interrupt power to the equipment in the event of an emergency.

The Future of Emergency Stop Technology

As technology continues to advance, the design and implementation of emergency stop buttons are also evolving to meet the changing needs of industrial settings. One area of development is the incorporation of electronic safety systems that provide enhanced functionality and communication capabilities for emergency stop buttons.

Modern e-stop systems may feature advanced sensors, networking capabilities, and diagnostics that enable real-time monitoring of the status and usage of emergency stop buttons. This level of connectivity can provide valuable insights into safety incidents, maintenance requirements, and the overall functionality of e-stop systems within a facility.

Furthermore, innovations in human-machine interface (HMI) technology are influencing the design of emergency stop buttons and their integration into control systems. Touchscreen interfaces, customizable displays, and interactive controls are being utilized to enhance the visibility and operability of e-stop functions, empowering operators to respond swiftly and effectively in emergency situations.

In the realm of industrial automation, the integration of emergency stop functions into the broader framework of safety systems is a focal point for enhancing overall safety and risk management. This includes the coordination of emergency stop buttons with other safety devices, such as light curtains, safety mats, and interlocks, to create a comprehensive safety network that can rapidly detect and respond to potential hazards.

Looking ahead, the future of emergency stop technology is likely to be characterized by further integration, intelligence, and adaptability, as industrial environments seek to continuously improve safety measures and mitigate risks associated with machinery and equipment operations.

結論

In conclusion, the emergency stop button serves as a crucial component of safety in industrial and manufacturing settings. With its ability to quickly halt machinery and equipment in emergency situations, the e-stop button plays a vital role in preventing accidents, protecting workers, and mitigating the potential for injury or damage.

The importance of emergency stop buttons extends beyond their immediate function, encompassing regulatory compliance, equipment integrity, and the cultivation of a culture of safety in the workplace. Proper design, placement, training, and maintenance are all essential aspects of ensuring the efficacy of emergency stop buttons within industrial environments.

As technology advances, the future of emergency stop buttons is likely to involve further innovation and integration into broader safety systems, enhancing their capabilities and adaptability in addressing the evolving needs of modern industrial operations. By prioritizing the presence and effectiveness of emergency stop buttons, industries can continue to uphold high standards of safety and well-being for their workers and facilities.